Driving Compliance & Quality ③: ISO 14644-7 Final Question – How Does Sensor Accuracy Affect Leak Detection?

Introduction

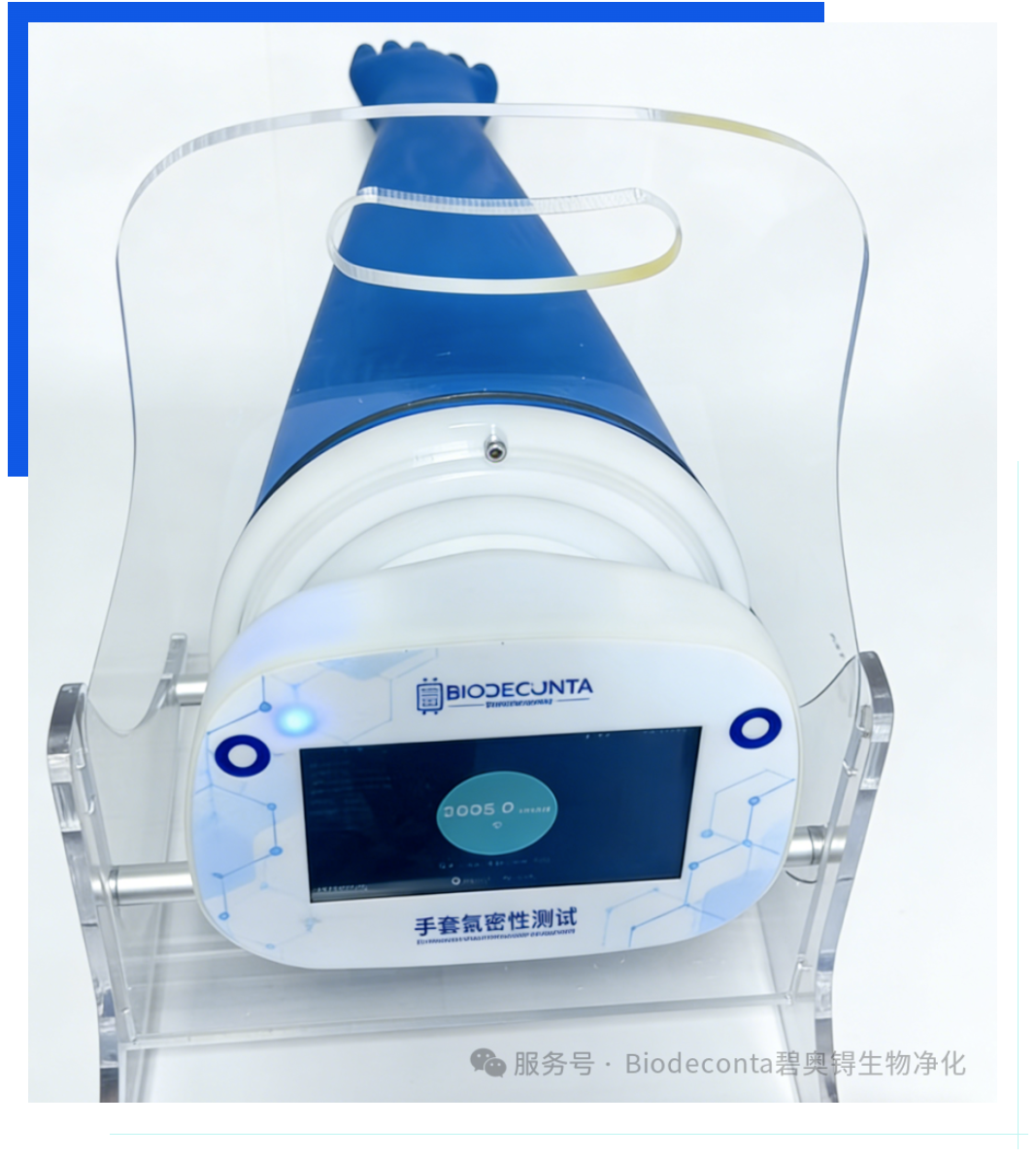

IntroductionAfter the in-depth interpretations of the previous two issues, we have clarified the pressure setting logic of ISO 14644-7 positive pressure testing and the core of PQ validation for leak size detection. As the final installment of the series, this issue focuses on the "key component" determining test system performance—the differential pressure sensor—answering the industry’s ultimate question: Does sensor accuracy affect the minimum detectable hole size? Why is accuracy a core indicator for evaluating equipment compliance?

Let’s uncover the "mystery" of sensor accuracy and conclude the series perfectly~

Clear Answer: Sensor Accuracy Defines the Detection Lower Limit

Clear Answer: Sensor Accuracy Defines the Detection Lower LimitIn glove integrity testing, pressure drop (ΔP) is the core indicator for judging glove leakage, and the reliability of ΔP directly depends on sensor accuracy. Simply put: The higher the sensor accuracy, the stronger the ability to identify tiny pressure changes, and the smaller the minimum detectable hole size.

Taking two common accuracy sensors as examples, their performance under the 1000 Pa range varies significantly:

Accuracy Level | Error Range under 1000 Pa | Minimum Identifiable ΔP (Theoretical) | Detectable Hole Size |

±0.2%FSV | ±2 Pa | ±2 Pa | Stably detect ≤100 μm |

±1.0%FSV | ±10 Pa | ±10 Pa | May not stably detect ≤200 μm |

Note: Actual detection capability is also affected by system noise, temperature drift, glove material response, and other factors.

Hidden Dangers of Insufficient Accuracy: Risk of Misjudgment or Missed Detection

Hidden Dangers of Insufficient Accuracy: Risk of Misjudgment or Missed DetectionInsufficient sensor accuracy directly leads to two serious consequences:

Missed Detection: ΔP signals from small leaks may be masked by system noise, causing the equipment to fail to identify qualified gloves and bringing contamination risks to aseptic production;

False Positives: Excessive system error may misjudge normal pressure fluctuations as leaks, leading to unnecessary glove replacement and increased production costs.

Both scenarios violate the core goal of aseptic manufacturing compliance, making sensor accuracy a crucial indicator in equipment selection.

Industry Chaos: Why Are Many Manufacturers Reluctant to State Accuracy?

Industry Chaos: Why Are Many Manufacturers Reluctant to State Accuracy?Astute partners may notice that many test equipment manufacturers prefer to emphasize "resolution" rather than "accuracy" in promotions. The reason is simple:

Resolution can be improved through software algorithm optimization, making it a "beautifiable" parameter; while accuracy is an inherent hardware property of the sensor, directly determining the equipment’s manufacturing cost and core performance, and cannot be easily improved through software. Some manufacturers choose to avoid this key parameter to cover up insufficient accuracy.

Conclusion: Accuracy Is the "Core Pass" to Compliance

Conclusion: Accuracy Is the "Core Pass" to ComplianceSensor accuracy not only affects test sensitivity but also directly determines the lower detection limit of the test system, making it a core parameter for evaluating whether the equipment truly meets ISO 14644-7 requirements. When selecting equipment, companies should clearly request sensor accuracy indicators from suppliers and comprehensively judge whether the equipment can meet their own production compliance needs based on PQ validation data.

Closing

ClosingSo far, the ISO 14644-7 positive pressure glove testing series has come to an end! In the three installments, we have answered three core questions: pressure setting, leak size detection, and sensor accuracy. We hope to provide practical technical references for your aseptic manufacturing compliance work.

Compliance and quality improvement in aseptic manufacturing is a continuous process of refinement. In the future, we will share more cutting-edge industry technologies, standard interpretations, and practical experience to support the joint development of industry partners. Thank you for your continuous attention—see you in our future content!

This article is an original work by BIODECONTA Innovation Inc. All rights reserved.

No part of this publication may be reproduced, excerpted, or used for commercial purposes without prior written permission.

The technical content herein is for reference only and may be updated or modified over time without prior notice.

BIODECONTA Innovation Inc. shall not be held liable for any direct or indirect consequences arising from the use of this information.

For citation or collaboration inquiries, please contact the company for formal authorization.

Follow us:

Related Products

Related Products