Biodeconta Shines at the 2025 PDI Conference

The Grand Conference Kicks Off, Biodeconta Arrives as Promised

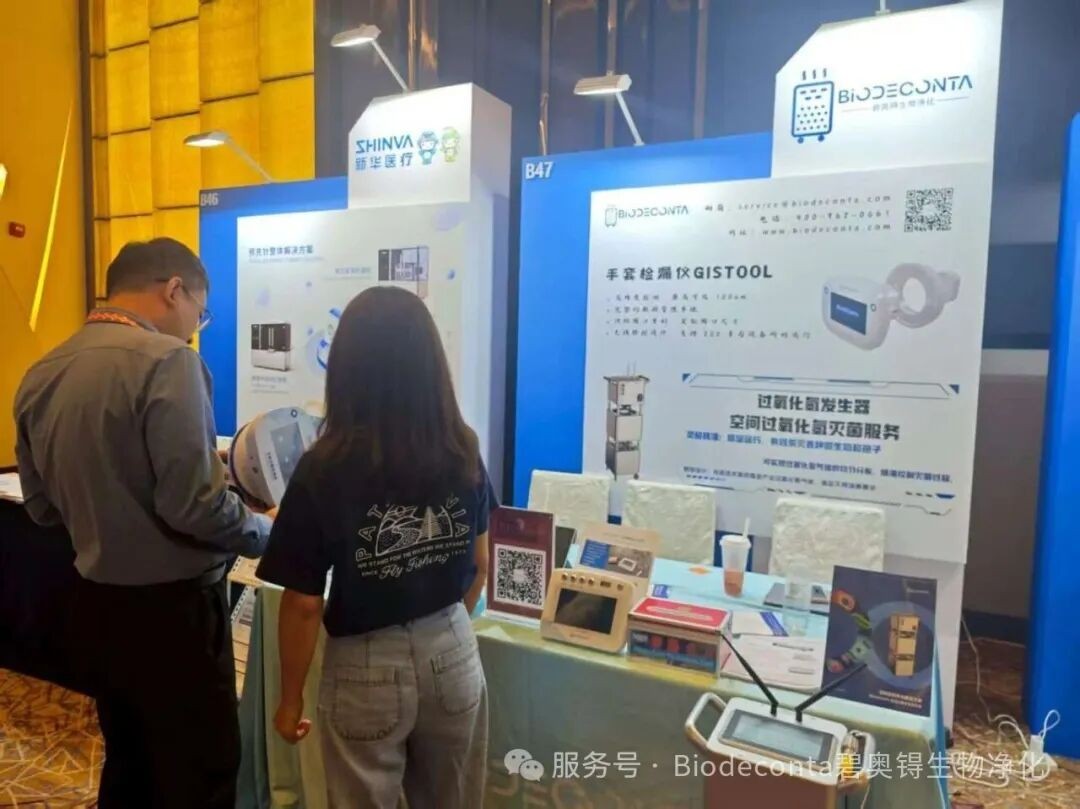

The Grand Conference Kicks Off, Biodeconta Arrives as PromisedAs the grand conference kicks off, Biodeconta arrives as promised. From September 3 to 5, 2025, Shanghai hosted a grand event for the pharmaceutical industry—the PDI Conference. Biodeconta actively participated in this industry gala, showcasing its capabilities and exchanging ideas and collaborating with numerous peers.

The PDI Conference, short for the Parenteral Drug Industry Conference, has focused on the parenteral drug sector since its establishment in 2008. It is dedicated to building a high-quality platform for learning, interaction, and collaboration in the sterile dosage form industry both domestically and internationally.

Over the past 18 years, with strong support from regulatory authorities, industry associations, research institutions, and enterprises at home and abroad, the PDI Conference has continued to grow and expand. Each year, more than 1,000 attendees participate, sharing professional knowledge and exchanging insights across various fields—including regulatory oversight and policies, industry trends, R&D, manufacturing quality, packaging and excipients, injection safety, supply chain security, and investment.

The 2025 PDI Conference, themed "Demand Upgrades and Industry Opportunities," was grandly held at the Baohua Howard Johnson Hotel in Shanghai, drawing widespread attention from within the industry.

GISTOOL

GISTOOLAs an enterprise deeply rooted in pharmaceutical-related fields, Biodeconta has long been committed to providing high-quality products and services to the industry. Leveraging its professional technical team, advanced R&D philosophy, and unwavering pursuit of quality, the company has built a solid reputation within the sector. Its business covers multiple key areas, aiming to deliver comprehensive sterile environment support for pharmaceutical production, R&D, and other processes.

At this conference, Biodeconta brought two highly competitive products and services. Among them, the GISTOOL series of glove leak detectors attracted significant attention—especially the GISTOOL-50 and GISTOOL-100, which play an irreplaceable key role in sterile pharmaceutical production.

The GISTOOL-50 is designed specifically for small-scale production environments or experimental scenarios requiring high detection precision. It adopts advanced pressure decay testing technology: a built-in high-precision air pump inflates gloves with precise pressure, which is then maintained for a set period to monitor pressure changes. Even extremely tiny leaks (with a detection precision of up to 100μm) can be 敏锐 captured by the GISTOOL-50. If the pressure fails to reach the set safety value after testing, the device will flag the test as failed, clearly alerting operators to potential glove leaks. This ensures the sterility of the production environment and minimizes the risk of drug contamination caused by glove leaks. In terms of operation, the GISTOOL-50 features a simple, intuitive interface—staff can master it after minimal training. Its robust data storage function can save thousands of offline test records for later query and traceability, ensuring every link in the production process is trackable. It fully complies with international standards such as FDA 21 CFR Part 11, providing strong support for enterprises’ compliant production.

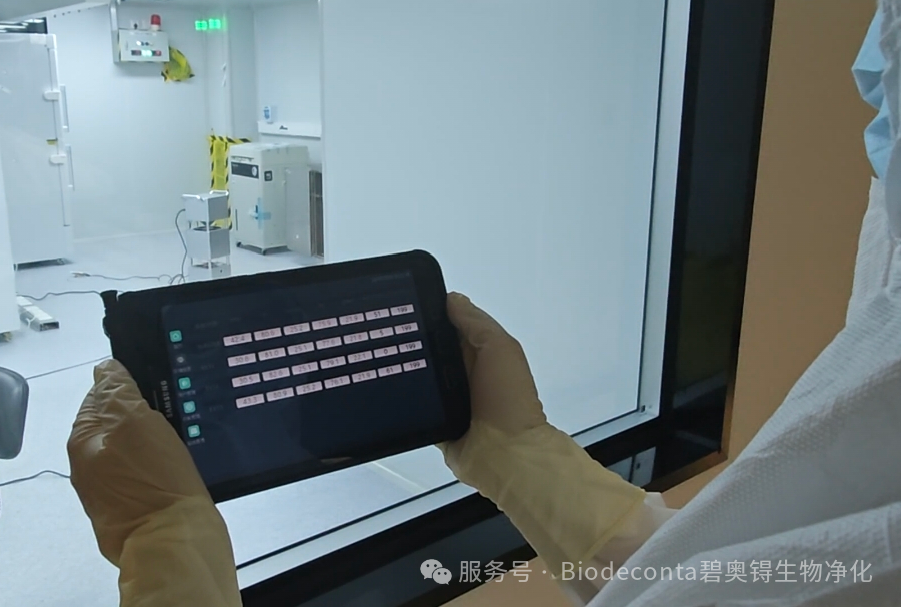

The GISTOOL-100, by contrast, focuses more on large-scale production needs, boasting excellent detection efficiency and stability. It can rapidly test multiple gloves simultaneously, significantly reducing single-test time and greatly improving overall detection speed—meeting the demand for efficient operation in large-scale production lines. Technically, the GISTOOL-100 also relies on a high-precision pressure monitoring system to ensure accurate and reliable test results. Additionally, it is equipped with wireless identification capabilities: it can automatically recognize glove IDs via RFID tags, eliminating manual recording and greatly enhancing work efficiency. Moreover, the GISTOOL-100 can seamlessly integrate with enterprises’ existing production management systems, enabling real-time data transmission and sharing. This facilitates comprehensive monitoring and management of production processes, supporting the intelligent and digital upgrading of pharmaceutical production.

Hydrogen Peroxide Purification Service

Hydrogen Peroxide Purification Service

Backed by advanced vaporized hydrogen peroxide technology, this service enables comprehensive purification of complex spaces. The service process is rigorous and standardized:

- A professional team first conducts a full assessment of the space to be purified, formulating a customized purification plan based on factors such as space volume and equipment layout;

- Subsequent environmental pre-treatment is carried out to remove impurities that may affect purification effectiveness;

- Specialized equipment is then used to vaporize hydrogen peroxide solution, allowing it to diffuse evenly in gaseous form to every corner of the space—including hard-to-clean areas such as gaps and pipelines;

- During the purification process, real-time monitoring of hydrogen peroxide concentration and environmental parameters is performed to ensure all preset purification criteria are met;

- After purification, professional measures are adopted to remove residual hydrogen peroxide, guaranteeing safe access for personnel.

Professionalism and rigor are equally reflected in the validation and handover process. Immediately upon completion of purification work, technicians conduct preliminary tests on the purification effect. Biological indicator verification is performed to confirm compliance with purification requirements. A detailed purification report is then compiled, containing various parameters during the process, test data, environmental assessment results, and other relevant content. Once the customer verifies and approves the report, both parties sign for confirmation, marking the official completion of service handover.

Additionally, Biodeconta provides subsequent follow-up services to address customer inquiries during usage, ensuring full satisfaction with the purification results.

Exhibition Details

Exhibition DetailsBiodeconta also actively collaborated with the PDI Conference to host a live stream themed "Exploring Cutting-Edge Technologies for Pharmaceutical Sterility Assurance", featuring a carefully curated lineup of diverse content. During the stream, the company’s product manager appeared on camera: first, they led viewers on an immersive booth tour, detailing the layout of Biodeconta’s exhibition area and the display of two core offerings—the glove leak detectors and hydrogen peroxide sterilization services. Next, the product manager delivered an in-depth product explanation: combining real-world cases, they vividly elaborated on the working principles, unique advantages, and application scenarios of the GISTOOL-50 and GISTOOL-100 glove leak detectors, while also providing a detailed breakdown of the hydrogen peroxide purification service’s process and validation handover procedures.

The live stream included multiple interactive segments: viewers could submit questions via bullet comments, which the product manager answered in real time. For frequently asked questions, the product manager provided focused responses and expanded explanations. Additionally, a lucky draw was held during the stream, with Biodeconta-branded notebooks and exquisite gifts awarded to actively participating viewers—greatly boosting audience engagement.

Statistics show that the live stream attracted tens of thousands of views and thousands of online interactive comments. It effectively communicated the company’s product features, technical strengths, and service philosophy to a broader audience, allowing those unable to attend the conference in person to gain insights into the company’s latest developments, further expanding the brand’s influence.

Biodeconta delivered an impressive performance at this conference. Numerous customers showed strong interest in its glove leak detectors, stopping by the booth one after another to inquire in detail about the product performance, operation methods, and maintenance key points. They recognized the product’s crucial role in ensuring production safety and spoke highly of its precise detection capabilities.

Customers also expressed great enthusiasm for the hydrogen peroxide purification services, focusing on aspects such as service coverage, the stability of purification results, and cost-effectiveness. Many customers discussed the potential for cooperation with Biodeconta’s staff on-site, hoping to introduce this service to improve the production environment quality of their own enterprises.

Biodeconta’s participation in this PDI Conference was a highly successful showcase. It not only enhanced the company’s brand visibility but also expanded opportunities for business cooperation. It is believed that in the future, Biodeconta will continue to shine in the pharmaceutical industry with its high-quality products and services, contributing more to the development of the sector.